Harrison M250 Lathe Manuals

Harrison M250 Lathe Instruction Manual, Maintenance Manual and Parts Manual as useful Exploded Assembly Diagrams. Includes electrical schematics and additional. Transcript of Harrison M250. Undertaking Maintenance The overall maintenance of the lathe is carried out by Bryan Ruby the Senior Technician of the engineering department in Kingston College. Chris Pickles, the Resource Manager, oversees the maintenance and ensures it is done correctly.

Undertaking Maintenance The overall maintenance of the lathe is carried out by Bryan Ruby the Senior Technician of the engineering department in Kingston College. Chris Pickles, the Resource Manager, oversees the maintenance and ensures it is done correctly and on time. Day to day cleaning is performed by any students who have used the lathe at the end of everyday. Maintenance Procedures Daily: Maintenance Procedures Weekly: Alignment: In order to align the saddle strips, tail stockbed clamps, cross-slide and top-slide correctly refer to the manual for the correct settings. Airlink101 Wireless N Usb Driver here. This allows for the cutting piece to accurately turn down the work piece and ensure even cuts, in order to meet the tight tolerances of the job.

Safety: Ensure that the emergency brake is correctly adjusted and stops the machine instantly when pressed. The changewheel shear pin should be checked to ensure it isn't damaged, to provide protection against accidental overload.

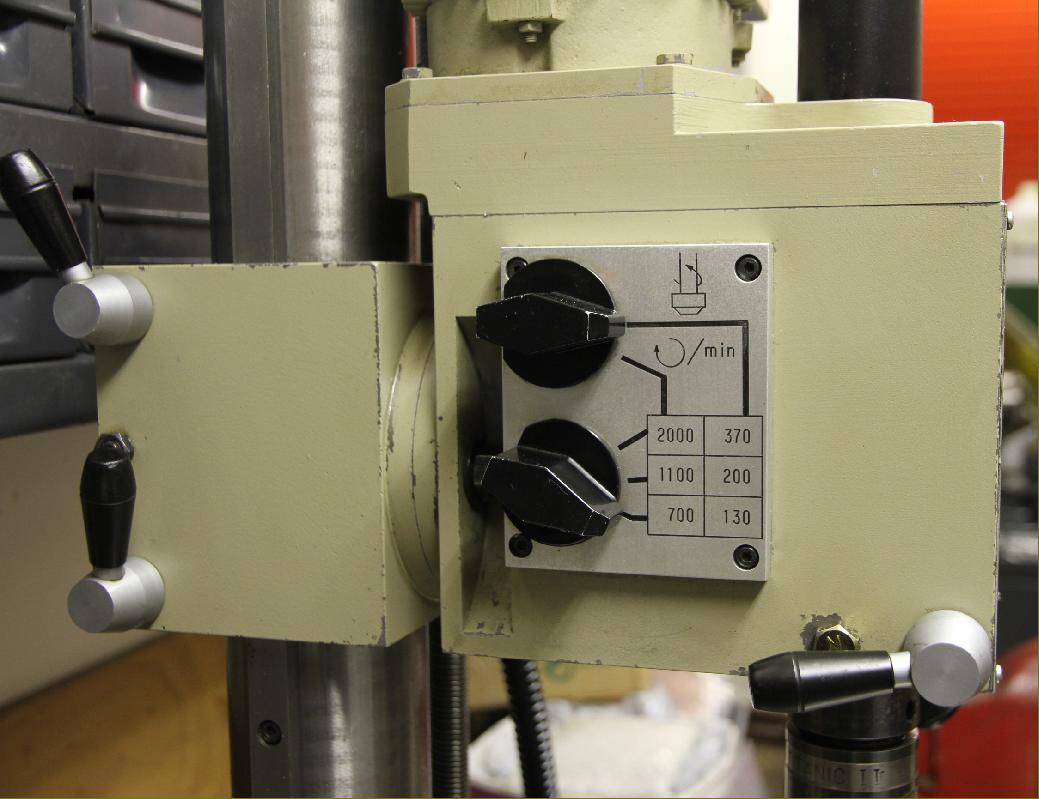

Maintenance Procedures Monthly: Belts: The vee belts that are used to run the chuck need to be adjusted periodically to remove any slack that may be present for this to be achieved the gearbox casing needs to be removed and the tensioning screws tightened to make correct adjustments against a straight edge. Harrison M250 280mm - 11in swing centre lathe The Harrison M250 Lathe was put into production in 1992 and was intended for the educational industry. Its compact size makes it the perfect lathe for people who have never used a lathe before. Colin Mcrae Rally 2005 Windows 7 32 Bit Patch Download on this page. The chuck is driven by a single phase motor which runs between 52 and 2000 rpm. The power is transferred between the motor and chuck via a vee belt. Cleaning: Brush away swarf, trefolex and any foreign objects from the chip pan. Remove all debris from slideways to allow proper lubrication and movement.